Low Pressure Molding

Low Pressure Molding Values

at a Glance

Protection against the Environment

Waterproof

Strain Relief

Impact and Vibration

Chemical Resistant

Weight Reduction

"Green" technology, No VOC & Low Waste

Cost Effective

Low Pressure Molding –

Improved Design Flexibility

Low Pressure Molding –

The Best Option for Part

Skylining

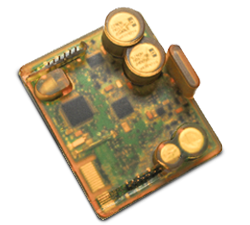

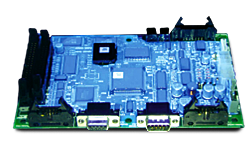

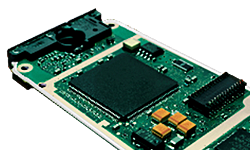

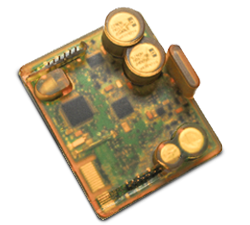

Material wraps the contours of components – with a minimum thickness of 1mm – encapsulating the PCB and reducing material usage through skylining.

Single-part, No-cure Materials

Hot melt thermoplastic that does not require mixing or curing.

Sustainable Materials

Low pressure molding materials are thermoplastics derived from plant-based fatty acids, are VOC free and REACH/RoHS compliant. The materials can be reworked and waste is

recyclable.

Custom-material Options

LPMS USA’s custom Spectra-Melt line incorporates additives and low-density fillers to enhance material properties, such as color, optical clarity, UV resistance and thermal stability.

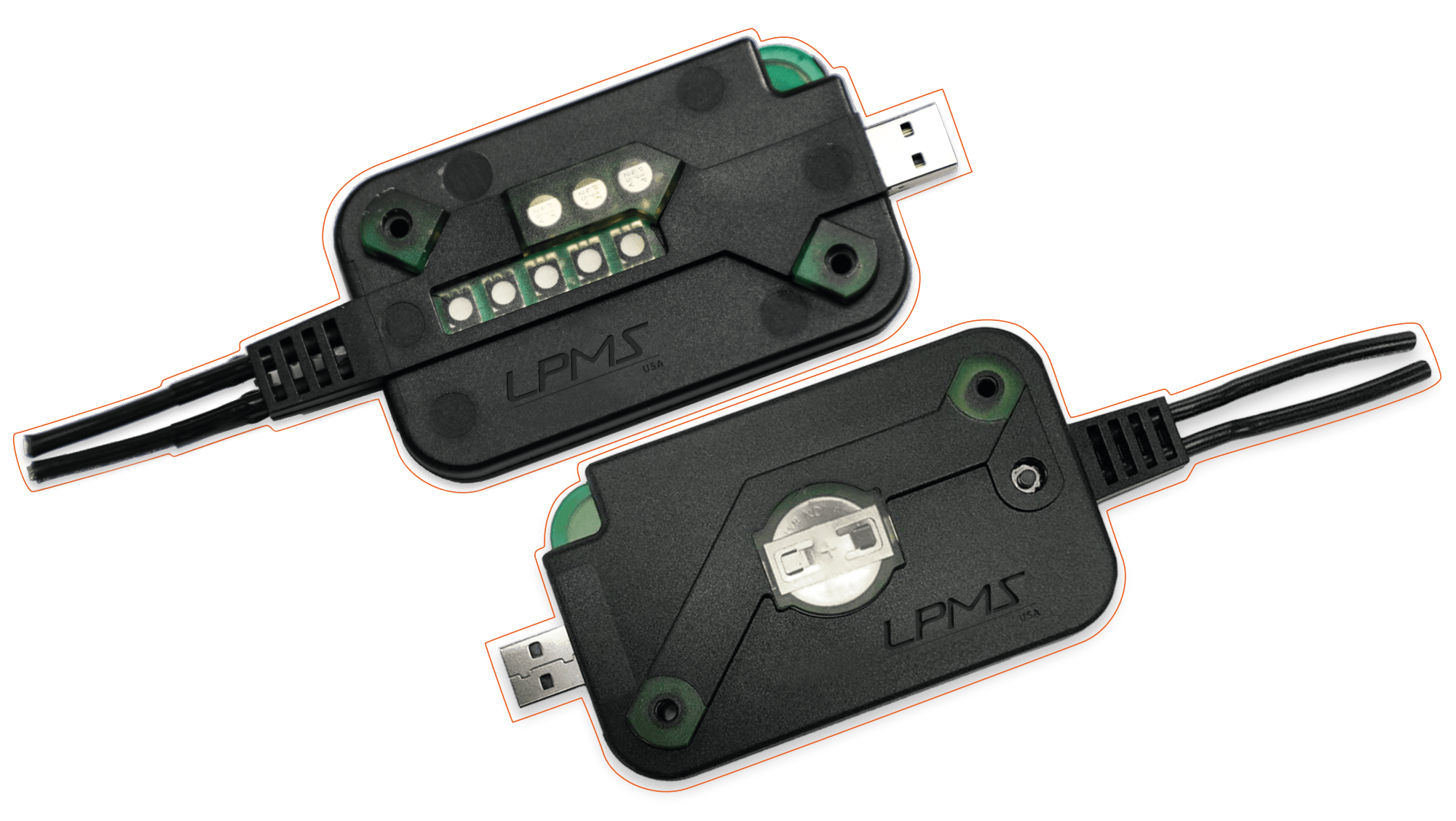

Strain Relief

Mechanically bonds to protect wires and cables to provide a waterproof seal. LPMS USA offers wire and cable processing and attachment prior to overmolding.

Overmolds Multiple Materials

LPMS USA’s dual-nozzle equipment platforms inject multiple materials at the same time, providing multiple PCB protection options.

Eliminates Housing

Low pressure molding materials become the housing, reducing cost, part numbers and inventory.

Bushings for Mounting

Compression-limiting bushings can be molded in place for parts mounting.

Embossing/Debossing

LPMS USA’s mechanical design engineers can integrate logos, part numbers and time stamps into the material.

Overmolds Batteries

Encapsulates and protects batteries withoutdamage.

Waterproof

Low pressure molding materials provide waterproofing and meet sealing requirements up to IP 69.

Shut Offs

Low pressure molding materials can shut off or mold around sensitive components, while still protecting electronics from moisture.

One Solution Provides

Multiple Protection Benefits

Learn more by exploring the infographic.

Potting Replacemet

• No Housing; fewer part numbers

• Improved aesthetic appearance; skylining

• Design flexibility, beyond form-fit-function

• Weight reduction

• Fast processing, short cycle times

• Watertight encapsulation

• No cure

• Strain reflief

• Reworkable

• Low waste

• No VOC

• Environment, chemical, moisture, thermal protection

• Suitable for batch processing

• New IPC standard published

Sealing Replacemet

• No Housing; fewer part numbers

• Improved aesthetic appearance

• No cure

• Moisture and chemical protection

• Electrical isolation

Conformal Coating Replacemet

• Temperature, vibration, impact and chemical-restart material

• Environmental protection (85°C/85%RH) available materials

• No cure

• Green technology

• Suitable for in-line processing

• Ne IPC standard published

Low Pressure Molding – Simplified Manufacturing Process

- Reduce your manufacturing steps (See Infographic)

- Reduce weight for your part

- Reduce your cycle time per part

- Reduce your material consumption

- Reduce your equipment & operations footprint

- Reduce your total cost of ownership

Low Pressure Molding –

Simplified Manufacturing Process

Traditional Potting Process Flow

Mold Plastic Housing

Parts to Assembly

Insert Electronics

Parts Preheating

Potting Dispense

Vacuum or Settle

Oven Cure

Parts for Test

Low Pressure Molding Process

Insert Electronics

Mold

Test Device

Protect with Low Pressure Molding –

it’s that simple.

Formulated Adhesive

Molding Resins

High-performance polyamide, polyolefin, and co-polyester materials

Thermoplastic materials, UL 94 V-0

80% of raw materials are based on renewables

No harmful fumes from molding process

Application viscosity from 1,000 to 10,000 cps

Application Pressure from 20 to 500 psi

Performance temperatures from -65°C to 200°C

Excellent adhesive properties to variety of substrates

Solvent-free, no safety labels

Long shelf life (2+ years)

RoHS and REACH complaint

Low Pressure Molding Compared

to High Pressure Injection Molding

| High Pressure Injection Molding | Low Pressure Molding | |

| Pressure | 25,000 PSI | 100 PSI |

| Temperature | 185–300+°C | 180–220°C |

| Material Viscosity | 5 grams over 10 min Melt Flow Rate

• Taffy

|

2,000–10,000 mPa•s (cP)

• Pancake syrup

|

| Applications |

• PCB Housings

• Tooth Brushes

• Bottle Caps

• Pocket Combs

• Plastic Parts

|

• PCBs

• Sensors

• Switches

• Batteries

• Connectors

|

| Equipment | Injection Molding Machine

• Screw barrel system

|

Low Pressure Molding Machine

• Gear pump system

|

| Clamping Pressure | 28–1,000 tons | 1–10 tons |

| High Pressure Injection Molding | |

| Pressure | 25,000 PSI |

| Temperature | 185–300+°C |

| Material Viscosity | 5 grams over 10 min Melt Flow Rate

• Taffy

|

| Applications |

• PCB Housings

• Tooth Brushes

• Bottle Caps

• Pocket Combs

• Plastic Parts

|

| Equipment | Injection Molding Machine

• Screw barrel system

|

| Clamping Pressure | 28–1,000 tons |

| Low Pressure Molding | |

| Pressure | 100 PSI |

| Temperature | 180–220°C |

| Material Viscosity | 5 grams over 10 min Melt Flow Rate

• Taffy

|

| Applications |

• PCB Housings

• Tooth Brushes

• Bottle Caps

• Pocket Combs

• Plastic Parts

|

| Equipment | Injection Molding Machine

• Screw barrel system

|

| Clamping Pressure | 28–1,000 tons |

Combined low pressures

and short cycle times

Temperature and injection time

Low Pressure

Molding Setup:

425°F (218 °C)

Mold set temperature:

70°F (21°C)

Cylindrical PCB over mold:

0.5” x 2.5” (1.27 cm x 6.35 cm)

Strong protection

Protection Ratings

| First Number: protection against solids |

Definition | Second Number: protection against liquids |

Definition |

| 0 | No protection | 0 | No protection |

| 1 | Protected against solid objects over 50 mm (e.g. accidental touch by hands) | 1 | Protected against vertically falling drops of water |

| 2 | Protected against solid objects over 12 mm (e.g. fingers) | 2 | Protected against direct sprays up to 15° from vertical |

| 3 | Protected against solid objects over 2.5 mm (e.g. tools and wires) | 3 | Protected against direct sprays up to 60° from vertical |

| 4 |

Protected against solid objects over 1 mm (e.g. tools, wires and small wires)

|

4

|

Protected against direct sprays from all directions – limited ingress permitted

|

| 5 | Protected against dustlimited ingress (no harmful deposit) | 5 | Protected against low pressure jets of water from all directions – limited ingress permitted |

| 6 | Totally protected angainst dust | 6 | Protected against strong jets of water (e.g. for use on shipdecks – limited ingress permitted) |

| 7 | Protected against the effects of temporary immersion between 15 cm an 1 m, Duration of test 30 min. | ||

| 8 | Protected against long periods of immersion under pressure |

| First Number: protection against solids |

Definition |

| 0 | No protection |

| 1 | Protected against solid objects over 50 mm (e.g. accidental touch by hands) |

| 2 | Protected against solid objects over 12 mm (e.g. fingers) |

| 3 | Protected against solid objects over 2.5 mm (e.g. tools and wires) |

| 4 |

Protected against solid objects over 1 mm (e.g. tools, wires and small wires)

|

| 5 | Protected against dustlimited ingress (no harmful deposit) |

| 6 | Totally protected angainst dust |

| Second Number: protection against liquids |

Definition |

| 0 | No protection |

| 1 | Protected against vertically falling drops of water |

| 2 | Protected against direct sprays up to 15° from vertical |

| 3 | Protected against direct sprays up to 60° from vertical |

|

4

|

Protected against direct sprays from all directions – limited ingress permitted

|

| 5 | Protected against low pressure jets of water from all directions – limited ingress permitted |

| 6 | Protected against strong jets of water (e.g. for use on shipdecks – limited ingress permitted) |

| 7 | Protected against the effects of temporary immersion between 15 cm an 1 m, Duration of test 30 min. |

| 8 | Protected against long periods of immersion under pressure |

Protection Levels of

Circuit Board Protection Technologies

Protection Levels of

Circuit Board Protection Technologies

Conformal Coating

Light mechanical protection

Sealing

IP 65-68 submersion protection

Potting

Robust; wide range/spikes in operating temperatures

Low Pressure Molding

Material and design flexibility (features); vibration dampening; IP 65-68 submersion protection

Waterproofing electronics

Securing Your Electronics from the Elements

Further Topics

Cost Savings Calculator

Our low pressure molding solutions open up great savings opportunities for you. Use our cost savings calculator to identify your individual savings potential.

Get in Touch

LPMS USA

1441 Branding Lane, Suite 110

Downers Grove, IL 60515 USA

Tel: +1 (800) 353-7773

Application Checklist

Tell us about your project, and an LPMS USA representative will contact you directly