Spectra-Melt

Low Pressure Molding Material for Advanced Applications

Spectra-Melt

Product Options

Spectra-Melt Standardized Adhesives

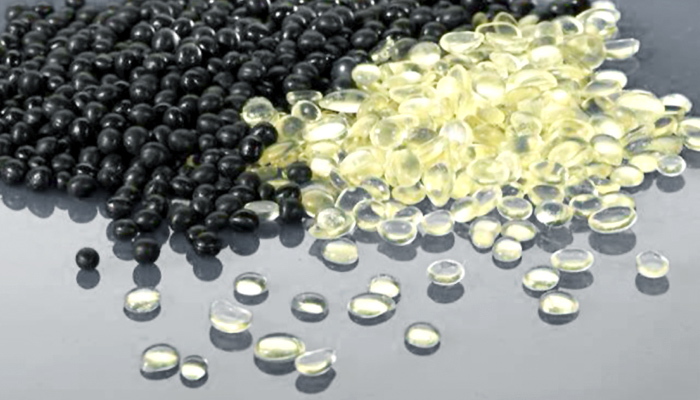

Spectra-Melt’s standardized adhesives in black and amber offer durable, high-performance solutions for various applications, including sensitive electronics. These adhesives provide waterproofing and long-lasting protection while enhancing process efficiency. For custom needs, our team can assist in selecting or formulating the right adhesive for your project. Curious about how Spectra-Melt can enhance your application? We’re here to help you find the perfect material solution.

Master Batches for Unlimited Color Options

Spectra-Melt

Product Highlights

Spectra-Melt SM 782

Thermoplastic hotmelt polyamide resin with excellent hardness and adhesion and UV stabilized. Suitable for wide range of applications such as automotive, strain relief, and electronic encapsulation.

Spectra-Melt SM 301

Spectra-Melt 282

Spectra-Melt 282 Blaze Orange color, PCB encapsulation used for automotive battery and high voltage applications, resistance to automotive fluids with good high-temperature creep resistance.

Spectra-Melt 216

Thermoplastic hot melt polyamide resin ideal for LED applications. It provides excellent optical clarity and brightness, fortified with a thermal antioxidant and stabilizer for long melt-tank life. Light-diffuser additive available to eliminate LED hotspots.

Spectra-Melt 858

Thermoplastic hot melt polyamide resin with best-in-class high-temperature creep resistance and hardness. It is resistant to automotive fluid splash exposure. This material is a replacement option for TECHNOMELT PA 2692.

OMEGA PURGE 200

Thermoplastic hot melt polyamide resin with excellent high-temperature resistance and stability for sealing electronics. It offers increased protection as a secondary overmold. It is resistant to automotive fluid splash exposure and is a replacement option for TECHNOMELT PA 2692.

Spectra-Melt

Complementary Materials

OMEGA PURGE 200

OMEGA PURGE 225

EPSILON MELT TANK CLEANER

The technical and safety data instructions for the Epsilon Melt Tank Cleaner help customers to maximise the safety of their tank cleaning process.

OMEGA RELEASE

Silicone and Phthalate free single component solvent based release system with low VOC. Ideal for low pressure molding to assist in easily removing parts from tooling with strong high temperature stability. Available in brush on and aerosol kits.

L.J. Adhesion Promoter and Primer

PRIMER 362 / CURATIVE 362

VertecBio ELSOL XR

VertecBio™ ELSOL® XR is a patented, bio-based and versatile solvent blend for formulations. Its better cleaning performance and lower solvent consumption make it the optimal replacement for xylene.

LPMS Melt Tank Instruction

Spectra-Melt

Advantages & Properties

Complements hot melt product lines with pigments and additives – Standard hot melts are amber and black

Nearly unlimited color options – Only requires Pantone number

Black light active and photoluminescent options

Low cost of entry

Color matching

Opaque or translucent option

Thermal stabilizers

Laser-marking additives

Light diffusers

UV stabilizers

Thermochromic

Anti-static

Request a sample

Further Topics

Cost Savings Calculator

Our low pressure molding solutions open up great savings opportunities for you. Use our cost savings calculator to identify your individual savings potential.

Get in Touch

LPMS USA

1441 Branding Lane, Suite 110

Downers Grove, IL 60515 USA

Tel: +1 (800) 353-7773

Application Checklist

Tell us about your project, and an LPMS USA representative will contact you directly