Find Your Printed Electronics Solution

With our Coating Guide, you’ll discover the best product for your market, application, and method.

LPMS Coating Guide for

Printed Electronics Technology

Materials

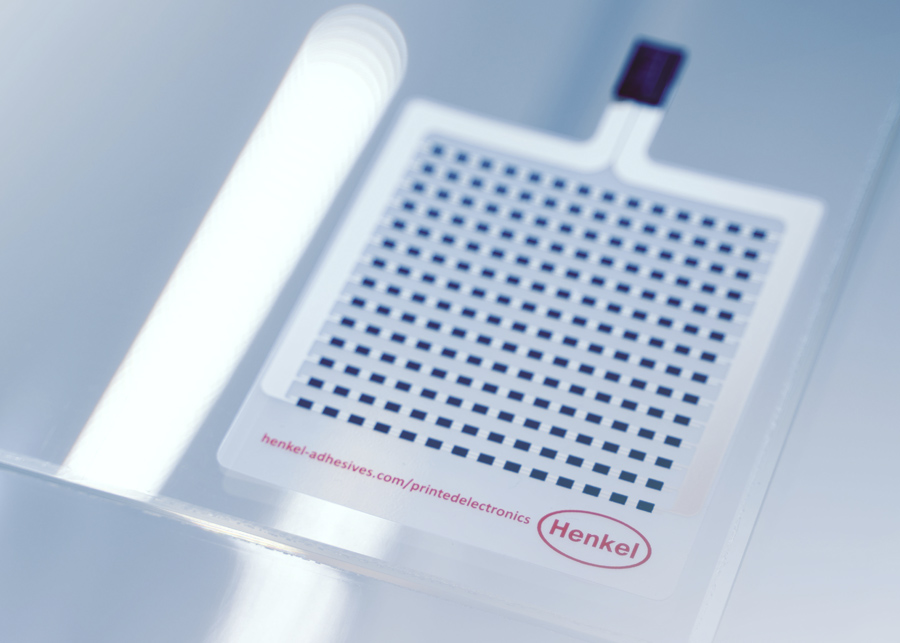

Henkel has a range of Electrically Conductive Adhesives (ECAs) suitable for Printed Electronics.

Conductive ink

and coating

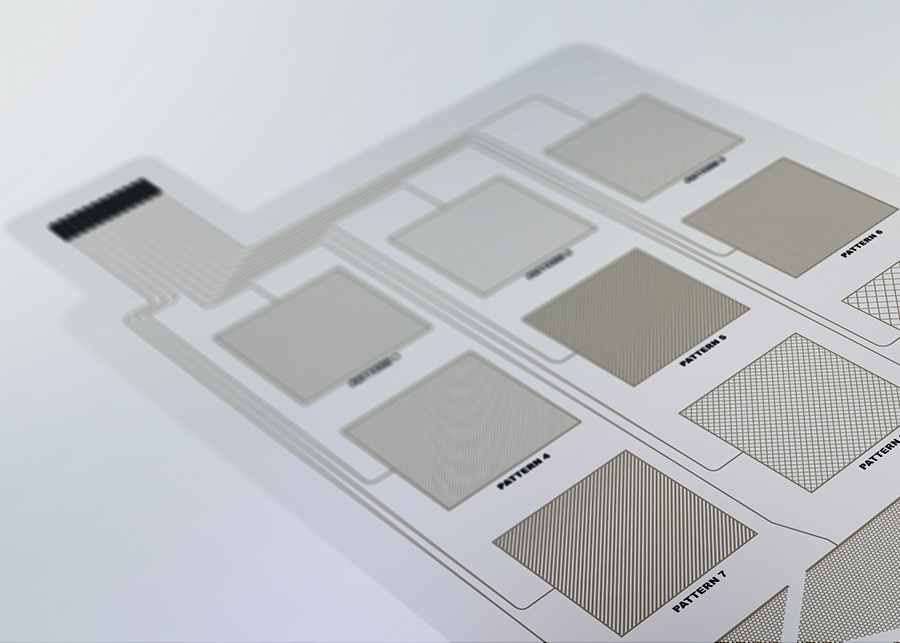

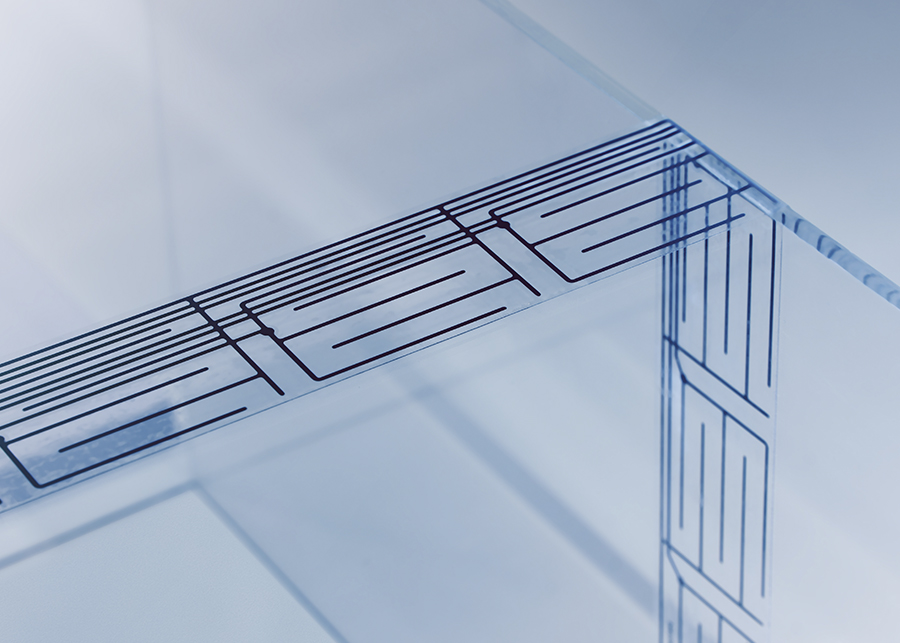

Conductive ink and coating formulations contain conductive particles for electrical conductivity. Henkel‘s LOCTITE® branded conductive ink portfolio covers different silver (Ag), silver/silver chloride (Ag/AgCI), and carbon ink (C) formulations as well as conductive coatings, including silver (Ag), carbon (C), copper (Cu), and nickel (Ni). Our LOCTITE® conductive inks are designed to print electronic components and circuits and are compatible with different substrates. Conductive inks can be used for many types of applications, including traditional electronic components, such as membrane switches, antennas, sensors, batteries, and more. Conductive coatings can be applied to shielding applications, including Electromagnetic Interference (EMI) applications.

Material Overview

| SILVER INK | SILVER/SILVER CHLORIDE INK | CARBON INK | SILVER/COPPER/CARBON / NICKEL COATING |

| LOCTITE® EDAG PF 006 E&C | LOCTITE® EDAG PE 007 E&C* | LOCTITE® EDAG PF 407A E&C | LOCTITE® EDAG 109 E&C* |

| LOCTITE® EDAG PD 056 E&C | LOCTITE® EDAG 965SS E&C | LOCTITE® EDAG PF 407C E&C | LOCTITE® EDAG SP 413 E&C |

| LOCTITE® EDAG PF 410 E&C | LOCTITE® EDAG PE 428E RC E&C* | LOCTITE® EDAG 423SS E&C | LOCTITE® EDAG 437 E&C |

| LOCTITE® EDAG PM406V1 E&C | LOCTITE® EDAG 7019 | LOCTITE® EDAG 440A E&C | LOCTITE® EDAG 440 AS E&C |

| LOCTITE® EDAG 418SS E&C | LOCTITE® EDAG 440B E&C | LOCTITE® EDAG 1415M E&C | |

| LOCTITE® EDAG PM 460A E&C* | LOCTITE® EDAG 965SS E&C | LOCTITE® EDAG 6041 E&C | |

| LOCTITE® EDAG 479SS E&C | LOCTITE® ECI 7001 E&C | ||

| LOCTITE® EDAG 725A (6S54) E&C | LOCTITE® ECI 7007 E&C* | ||

| LOCTITE® ECI 1001 E&C | |||

| LOCTITE® ECI 1006 E&C | |||

| LOCTITE® ECI 1010 E&C | |||

| LOCTITE® ECI 1011 E&C | |||

| LOCTITE® ECI 1014 | |||

| LOCTITE® ECI 1016 | |||

| LOCTITE® ECI 1203 E&C | |||

| LOCTITE® ECI 1204 E&C | |||

| LOCTITE® ECI 1205 E&C | |||

| LOCTITE® ECI 1216 E&C | |||

| LOCTITE® ECI 1217 E&C | |||

| LOCTITE® ECI 1501 E&C |

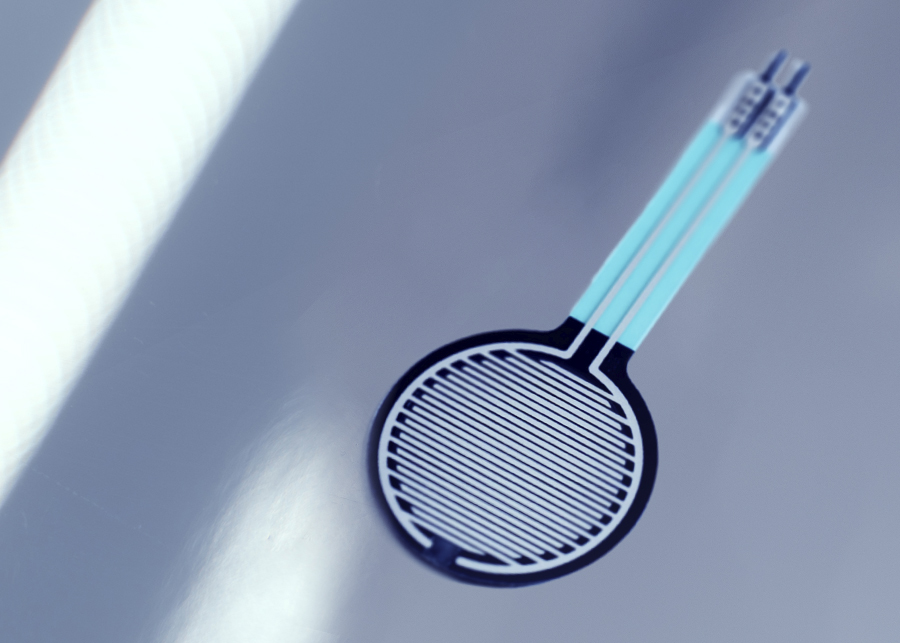

Resistive inks

Resistive inks are formulations based on different conductive inks containing conductive and non-conductive particles. This allows for the adjustment of resistance levels according to the application requirements. Henkel‘s LOCTITE® branded portfolio of resistive inks includes carbon (C), carbon positive-temperature-coefficient (PTC), and non-conductive blendable inks. Our LOCTITE® resistive inks are designed for printing electronic components, such as printed resistors, potentiometers, force-sensitive resistors (FSR), heating elements, and more.

Material Overview

| CARBON INK | CARBON PTC INK | NON-CONDUCTIVE BLENDABLE INK |

| LOCTITE® EDAG 6017SS E&C | LOCTITE® ECI 8001 E&C | LOCTITE® EDAG PM 404 E&C |

| LOCTITE® ECI 7004HR E&C | LOCTITE® ECI 8060HV E&C | LOCTITE® NCI 7002 E&C |

| LOCTITE® ECI 7004LR E&C | LOCTITE® ECI 8090 E&C | LOCTITE® NCI 8002 E&C |

| LOCTITE® ECI 8120 E&C |

Dielectric ink

Henkel’s LOCTITE® branded dielectric inks are designed for printing dielectric layers, conformal coatings, and encapsulations.

Material Overview

| DIELECTRIC INK | |

| LOCTITE® EDAG PF 021 E&C | LOCTITE® EDAG 451SS E&C |

| LOCTITE® EDAG 452SS E&C | LOCTITE® EDAG PF 455B E&C |

| LOCTITE® EDAG PF 455BC E&C | LOCTITE® EDAG 456 E&C |

| LOCTITE® EDAG PF 465 E&C | LOCTITE® EDAG ML 25208 E&C |

| LOCTITE® EDAG ML 25240 E&C | LOCTITE® EDAG ML 25265 E&C |

| LOCTITE® NCI 9001 E&C | LOCTITE® NCI 9006 E&C |

Application

Methods

Printed electronics can be created using various printing methods, including screen printing, rotary screen, flexographic, or rotogravure techniques. The choice of method depends on factors like production volume, application type, and material or substrate compatibility.

Conventional

Printing Methods

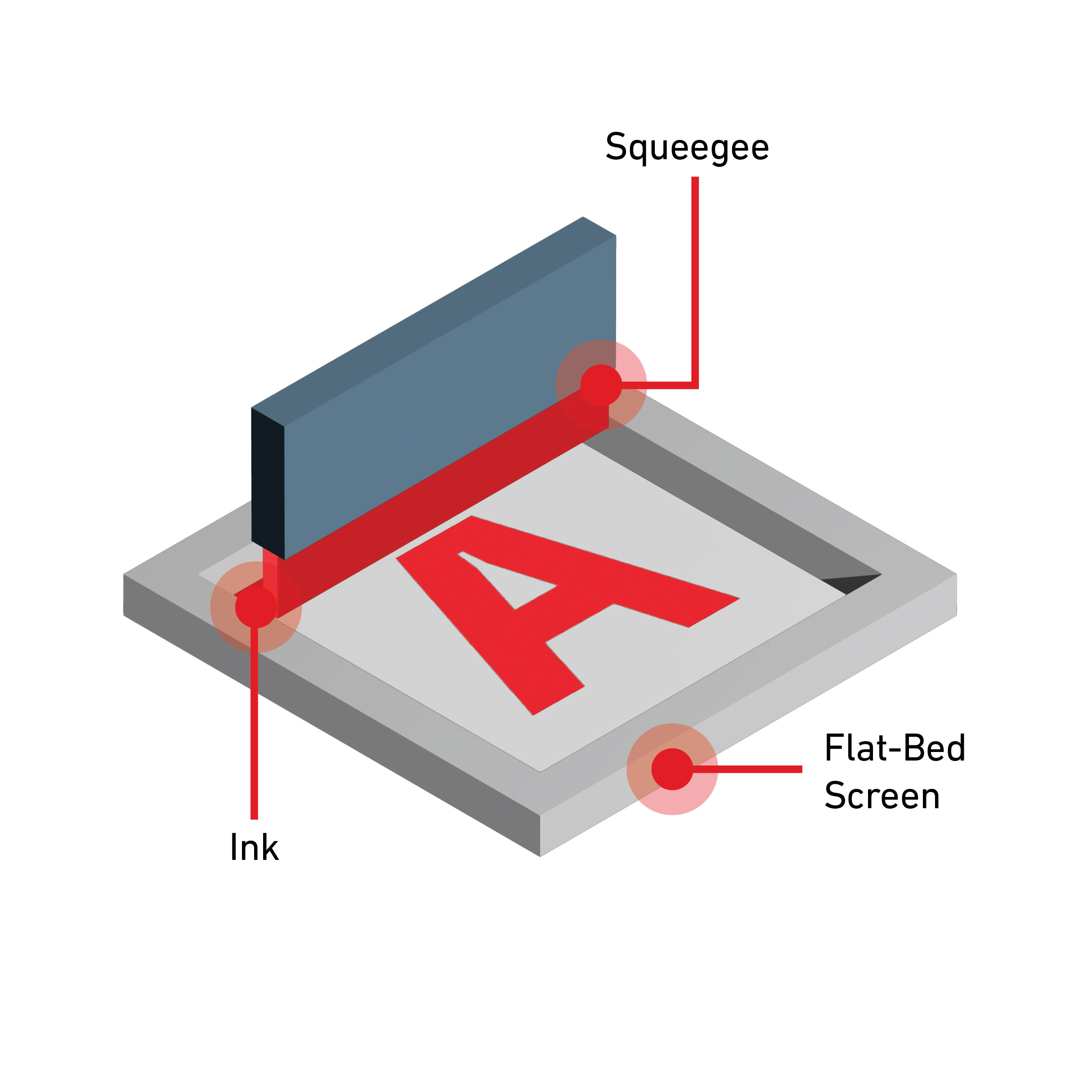

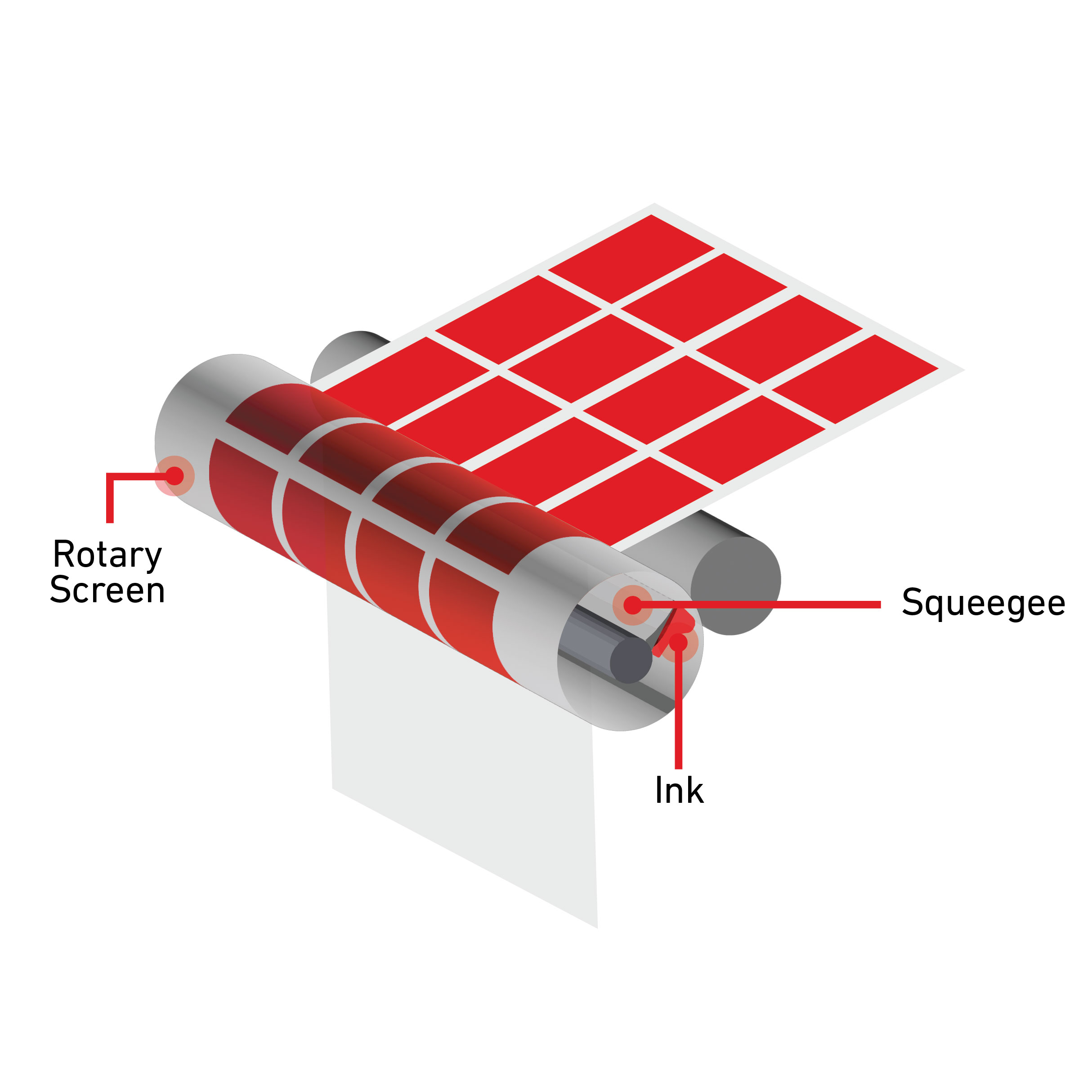

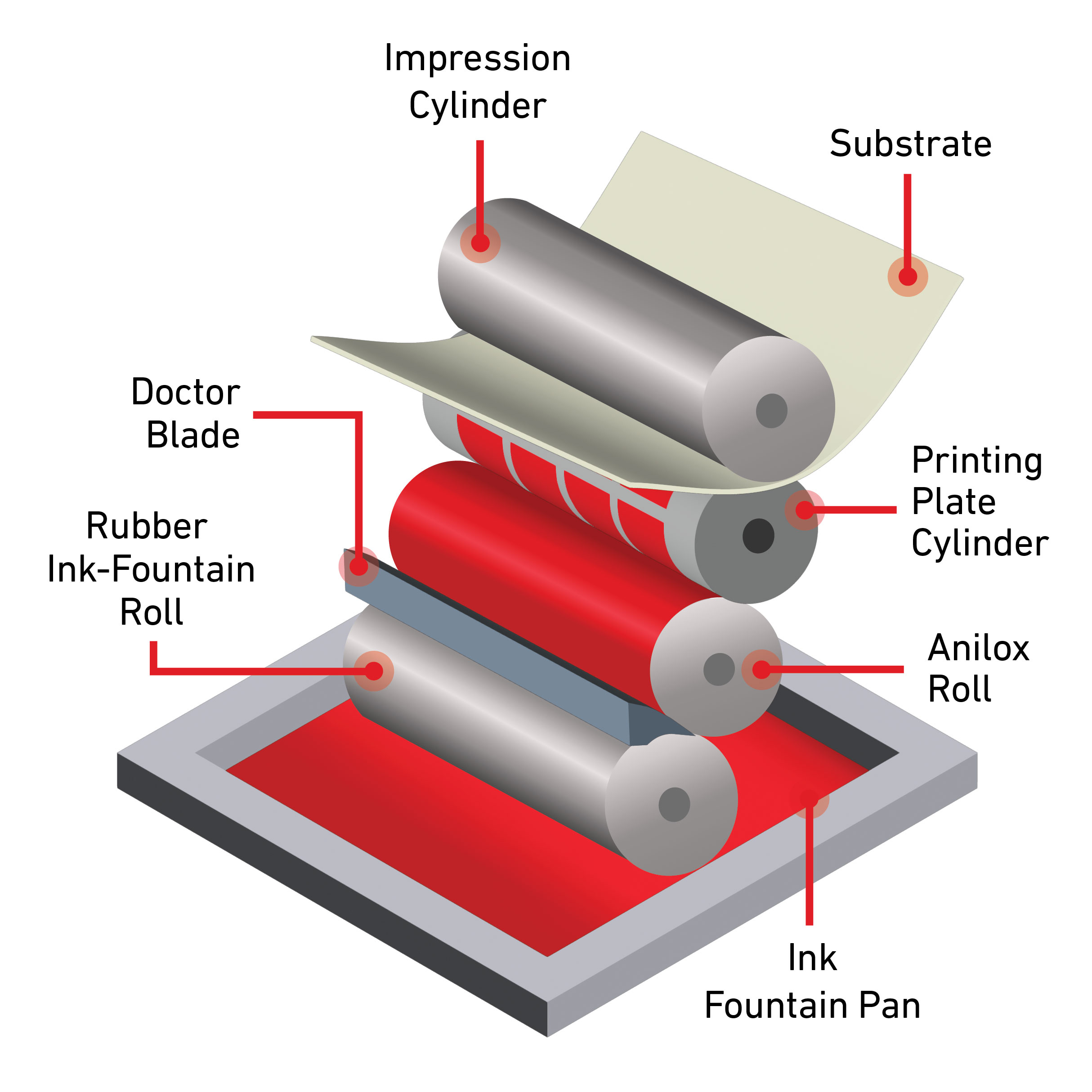

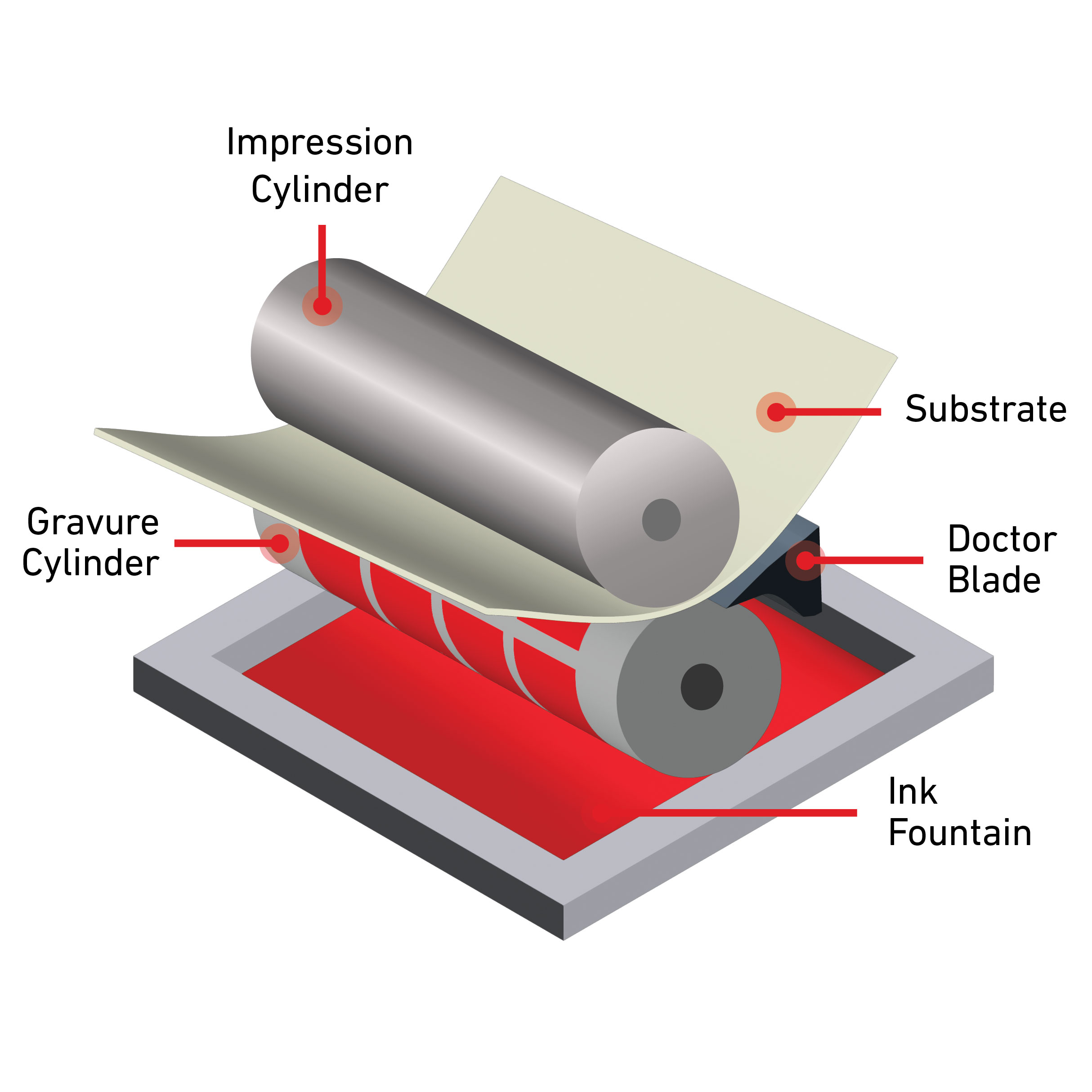

Conventional methods such as screen printing, flexography, and rotogravure offer scalability and precision for diverse applications. Screen printing excels in applying thick layers (5–25 μm) with high consistency, while flexography and rotogravure ensure faster production speeds and uniform thin coatings for large-scale manufacturing.

Flat-Bed Screen

Rotary Screen

Flexography

Rotogravure

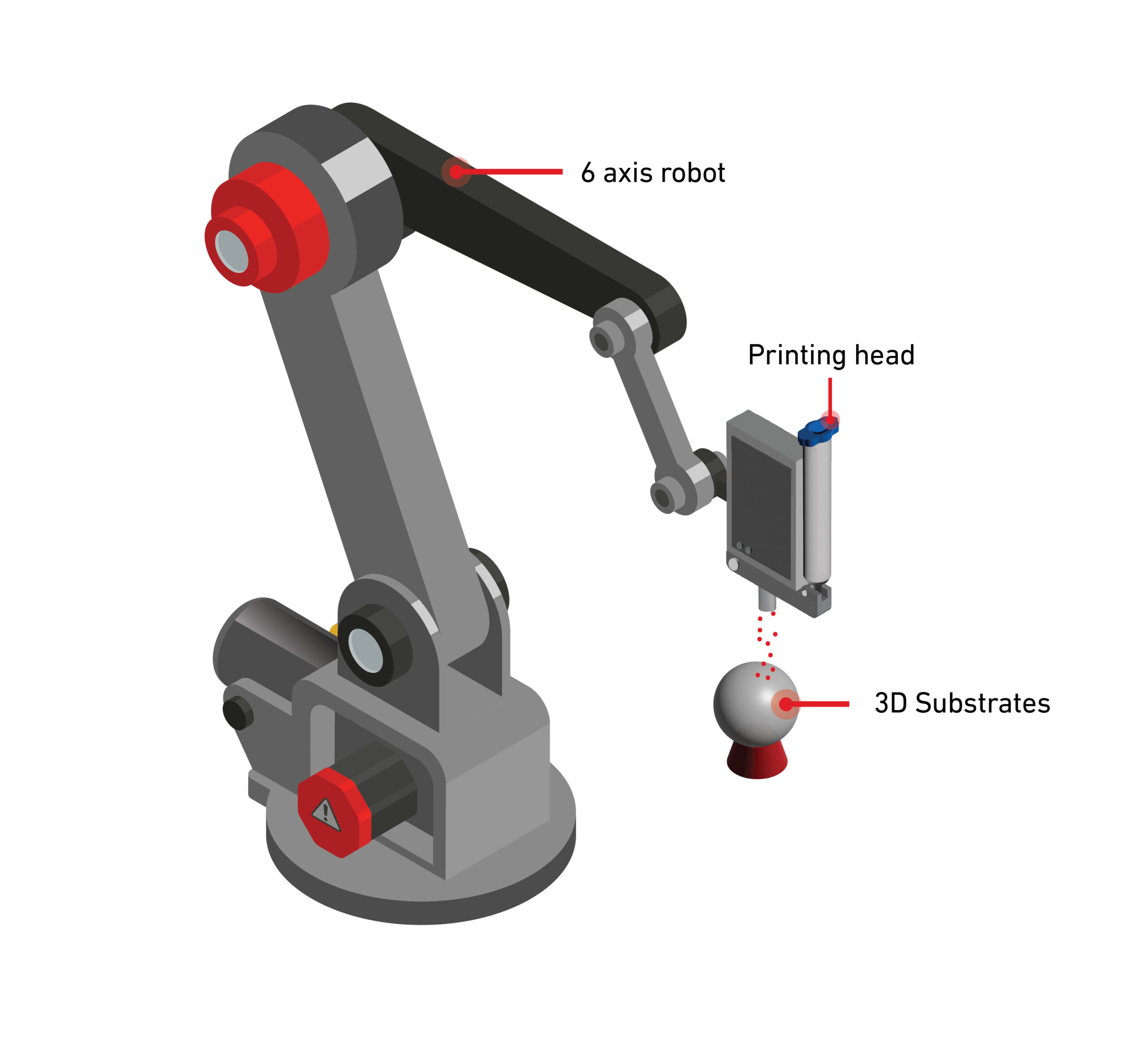

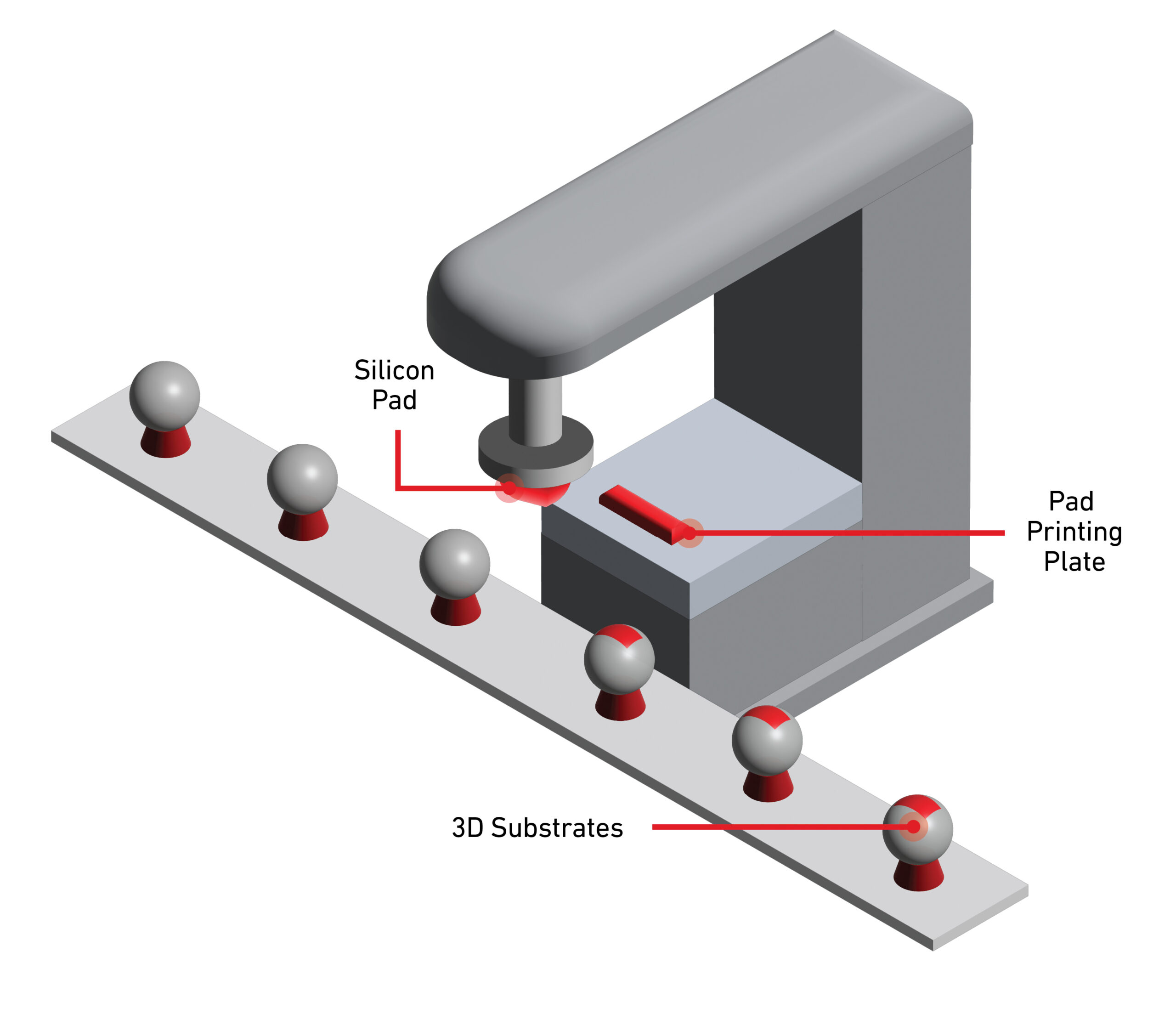

3D Printing Methods

3D printing techniques, such as direct 3D and pad printing, enable precise coatings on 3D-shaped surfaces. Pad-printable functional inks allow direct application without the need for wires, etching, or electroplating. Direct 3D printing uses a printing head attached to a robotic arm, adjustable for various coating processes, including spray-coating, valve-jet dispensing, aerosol jet, and dispensing. These methods enhance flexibility and efficiency, making them ideal for complex manufacturing requirements.

Direct 3D printing

Pad printing

Printed Electronics Markets

and Applications

Smart Surfaces

Applications

Printed Heaters

Membrane Switches

Capacitive Sensors

Resistive Sensors

Force-sensitive

Resistors

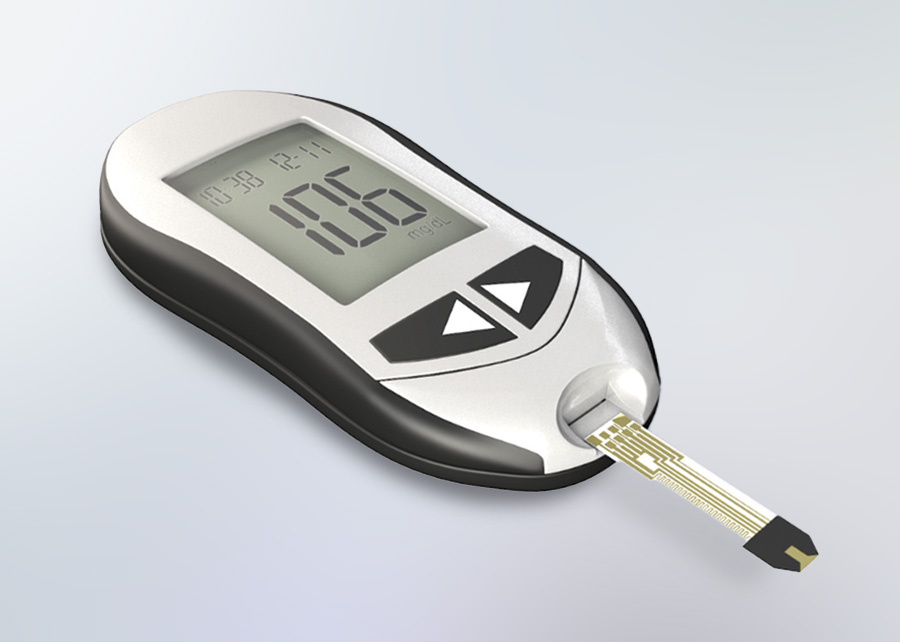

Healthcare

Applications

Printed Sensor for

Diagnostics and Hygiene

Medical Wearables

Medical Heaters

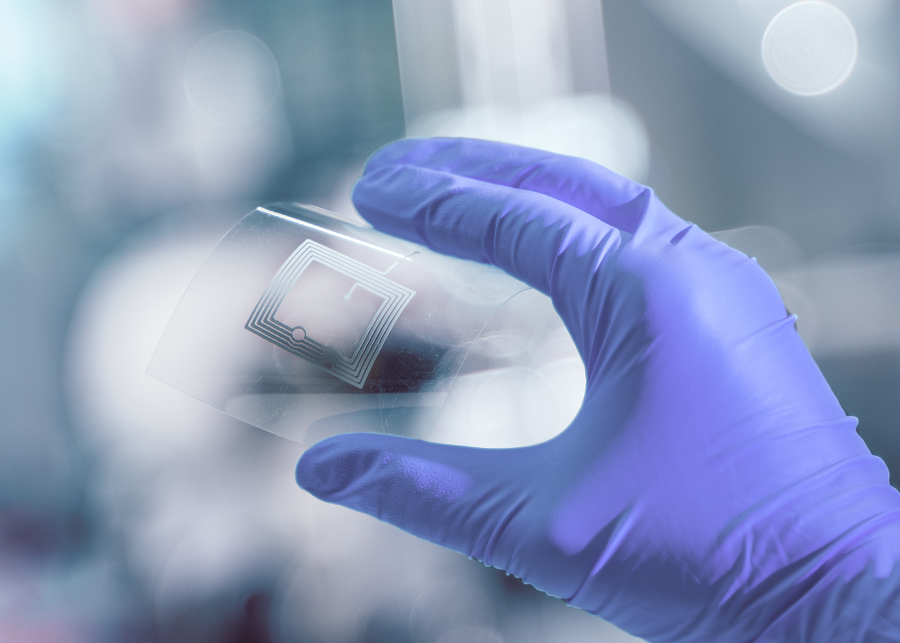

Antenna for

Medical Wearables

Antenna

Applications

Pad-printable Antenna

Printed RFID Antenna

Energy Storage

Applications

Energy Storage

Carbon-based inks for batteries, supercapacitors, and printed energy storage solutions, delivering improved safety and performance.

Further Topics

All Printed Electronics Products

Explore our complete portfolio of functional inks and coatings, designed for advanced printed electronics and optimized manufacturing.

Get in Contact

Application Guide

Printed Electronics Technology:

Driving Innovation Across Industries

Core Advantages of

Printed Electronics Technology

Advanced printing methods allow for faster production compared to conventional techniques, reducing lead times and increasing scalability.

Material Efficiency

Minimal material waste during production aligns with global sustainability goals while reducing costs.

Versatility

Flexible circuits can be designed for a wide range of applications, including wearable electronics, smart packaging, and medical diagnostics.

Printed Electronics

Materials

Conductive Inks

Resistive Inks

Dielectric Coatings

Advanced

Application Methods

Inkjet Printing Electronics

Pad Printing Electronics

Additive Manufacturing

Opening new possibilities for custom designs and advanced electronics integration.

Key Markets and

Applications

Consumer Electronics

Wearables, smart packaging, and home automation bring intelligent technologies into everyday life.

Sustainability in

Printed Electronics

Reduced Material Waste

Energy Savings